The Limo

Event Location: Cocoa-FL

Competition: Junior Solar Sprint

Division: 4-6 (JSS Green)

School: Pine Crest School

Team Size: 2

Pine Crest Engineering

The Limo- Built to Perfection

We went through the whole process of prototyping and engineering a solar car and the outcome is a vehicle with dumbfoundingly high performance.

Journal Entries:

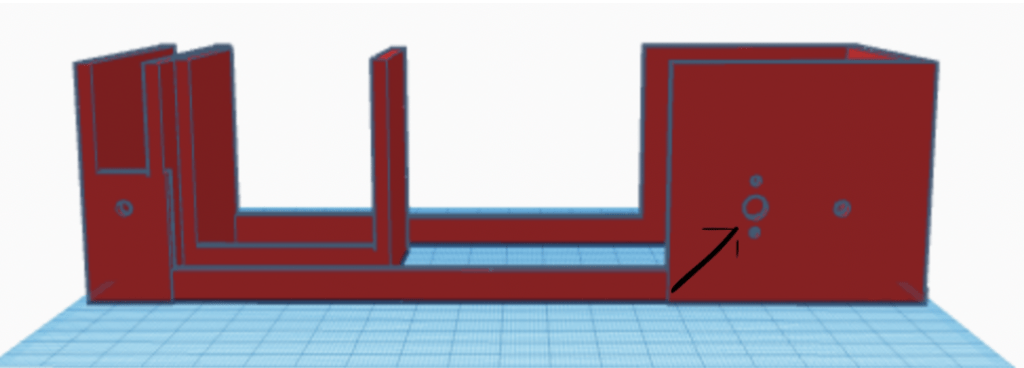

Entry 1: January 24 2022

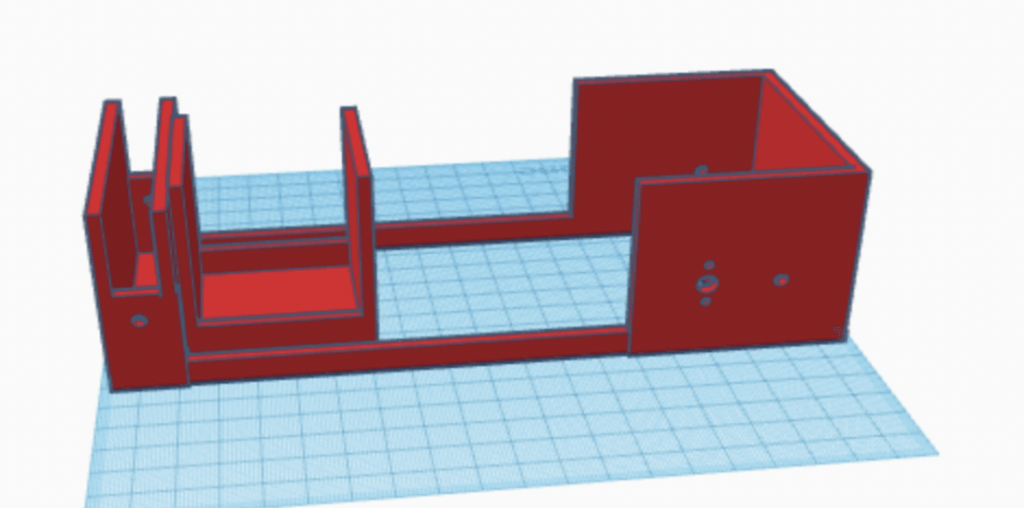

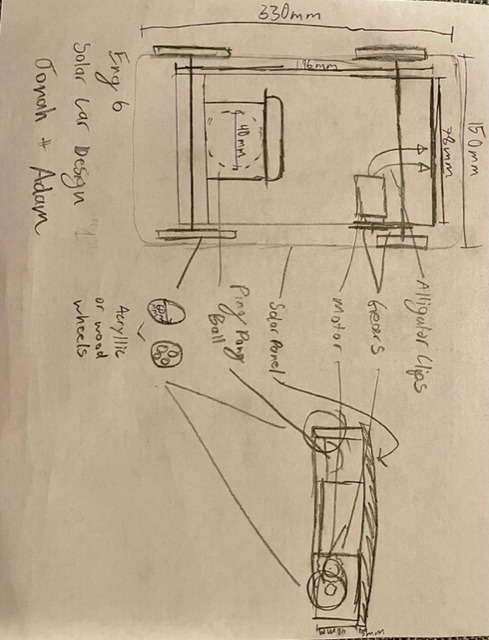

We started off our project and thought deeply about where our ball would go, where our motor would go and where the wheels would go. We are thinking of a sports car-like design, with a long body and low to the ground. (Team Members Present: Adam and Jonah)

Entry 2: January 31 2022

We’re still waiting for our car to be printed. We’re messing around with a cardboard design now, seeing what might work for our real car. (Team Members Present: Adam and Jonah)

Entry 3: February 7 2022

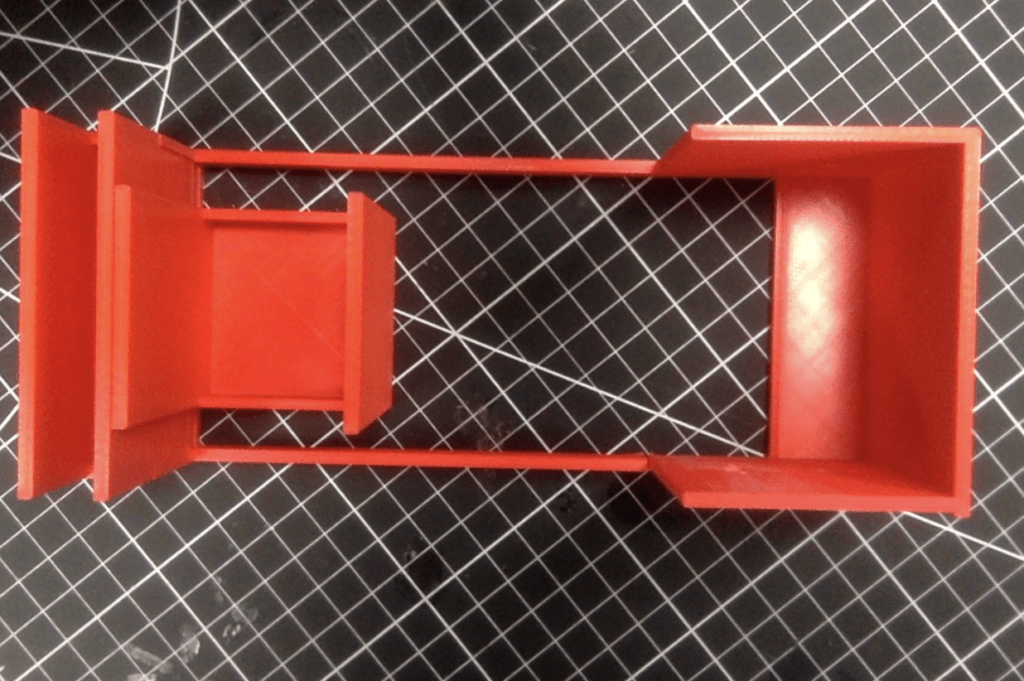

Let’s go! Our body design finally printed out! We can’t wait to add our motor! (Team Members Present: Adam and Jonah)

Entry 4: February 14 2022

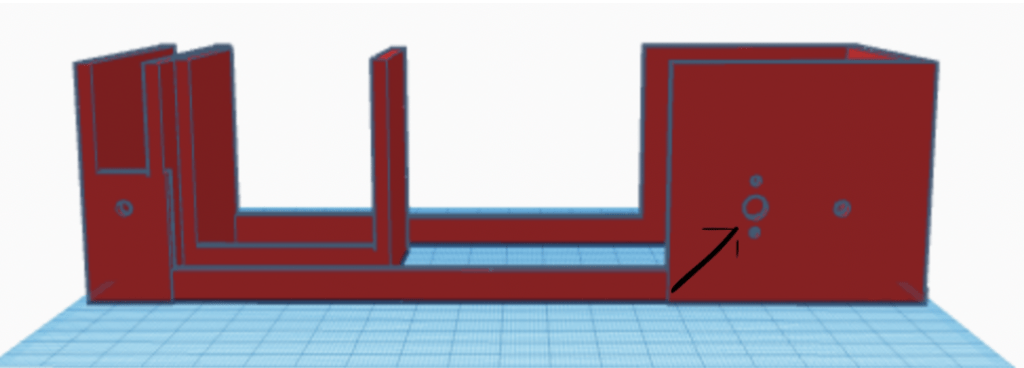

It turns out that we forgot a hole for our engine and the holes where the screws would go also don’t line up, so we are making a new design for our car! (Team Members Present: Adam and Jonah)

Entry 5: February 21 2022

Our new design is still printing, back to the cardboard prototype I guess… (Team Members Present: Adam and Jonah)

Entry 6: February 28 2022

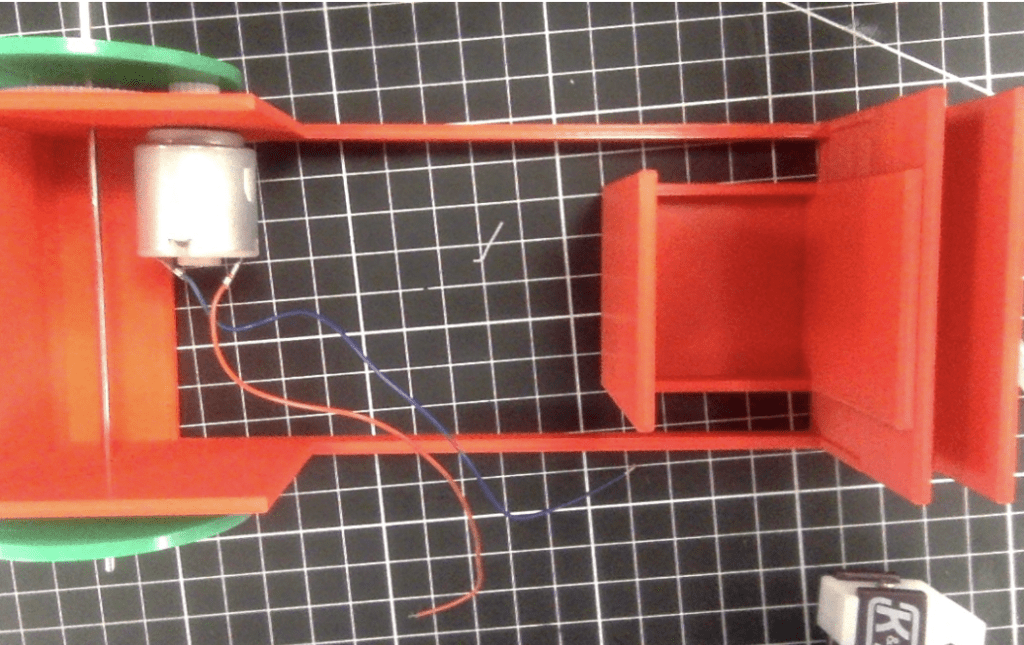

Now that our new design is printed, we will need to finish connecting the alligator clips to the motor and solar panel, as they don’t work right now. (Team Members Present: Adam and Jonah)

Entry 7: March 7 2022

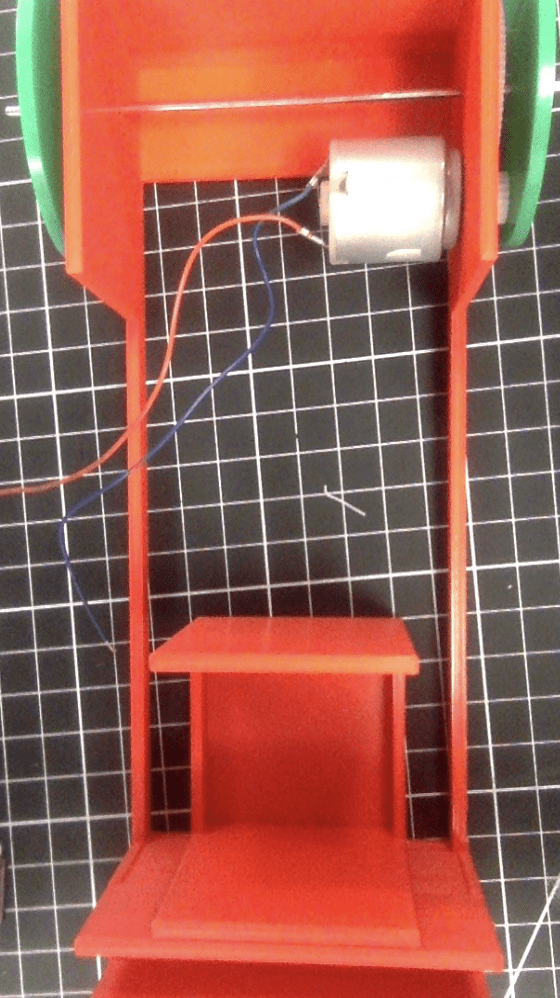

Turns out our solar panel was no good, so we replaced that right away! We are now trying to add the motor to the car. (Team Members Present: Adam and Jonah)

Entry 8: March 14 2022

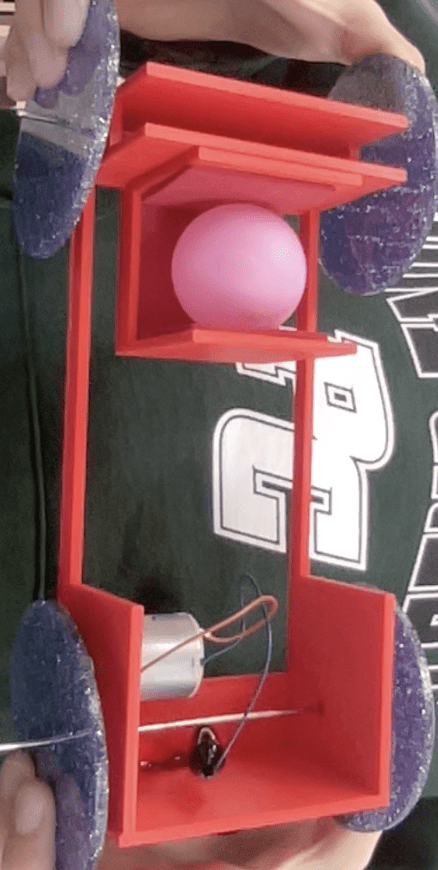

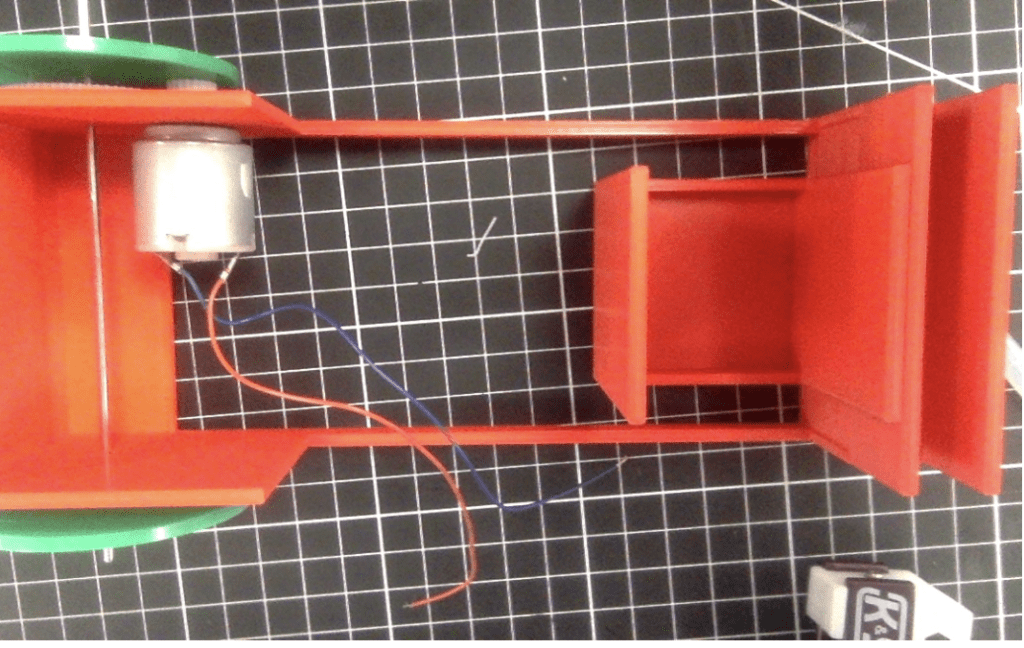

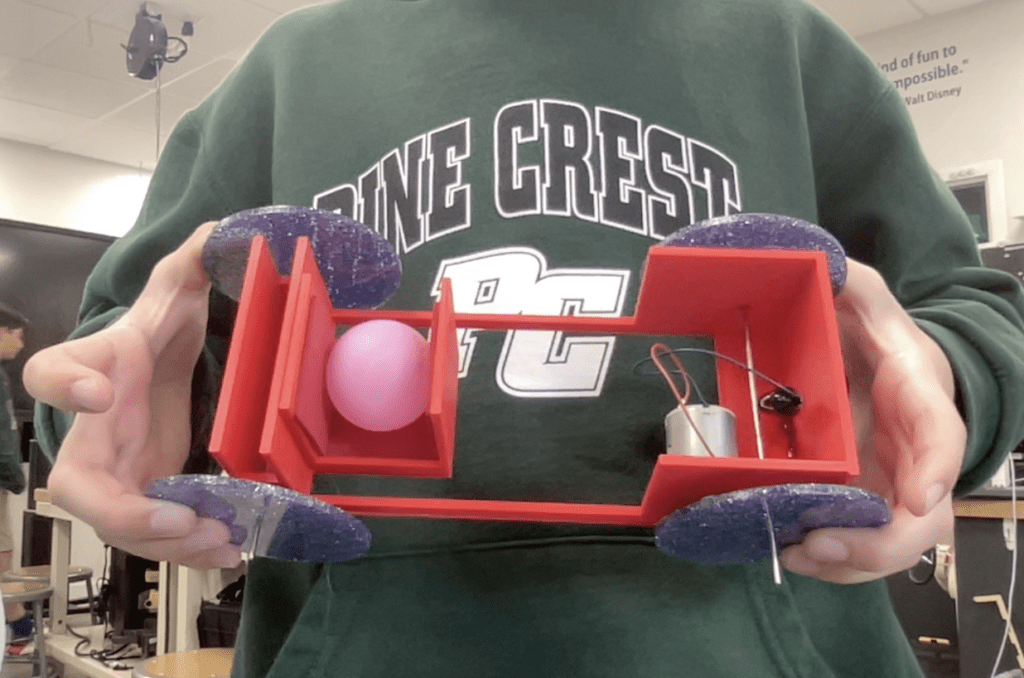

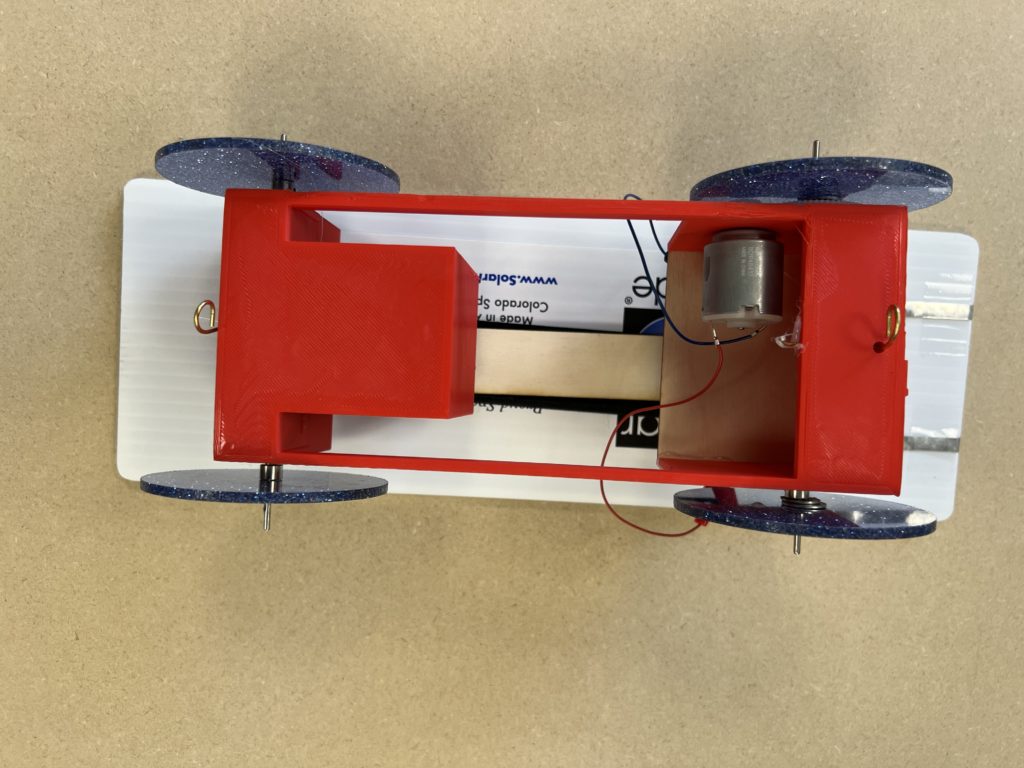

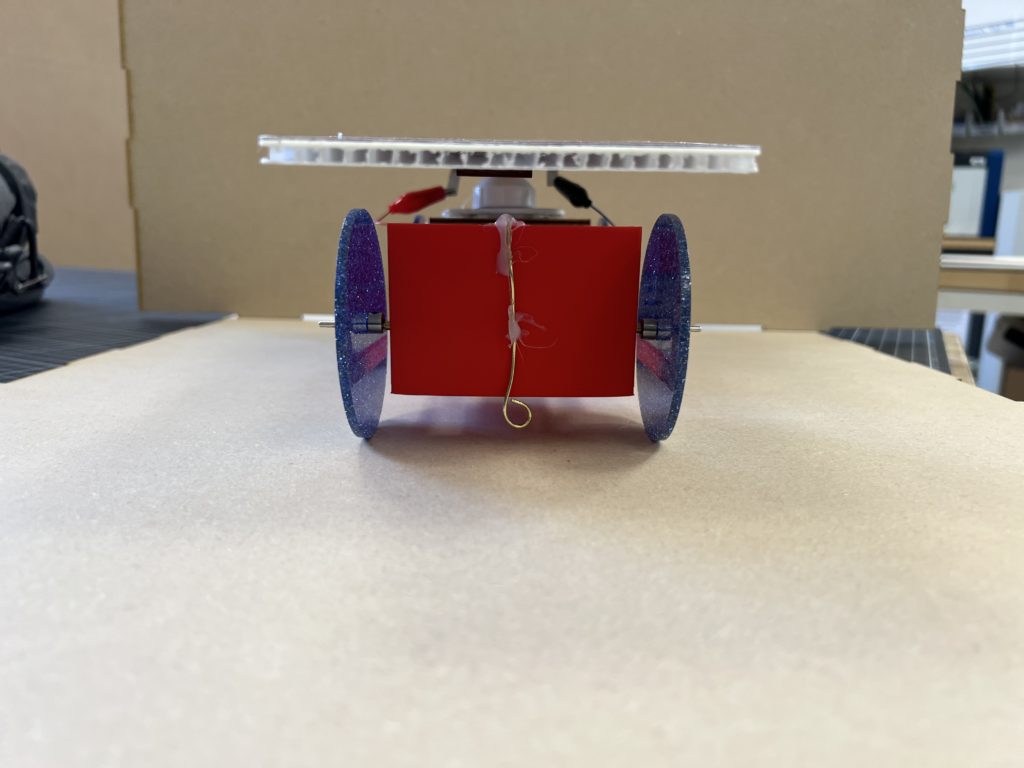

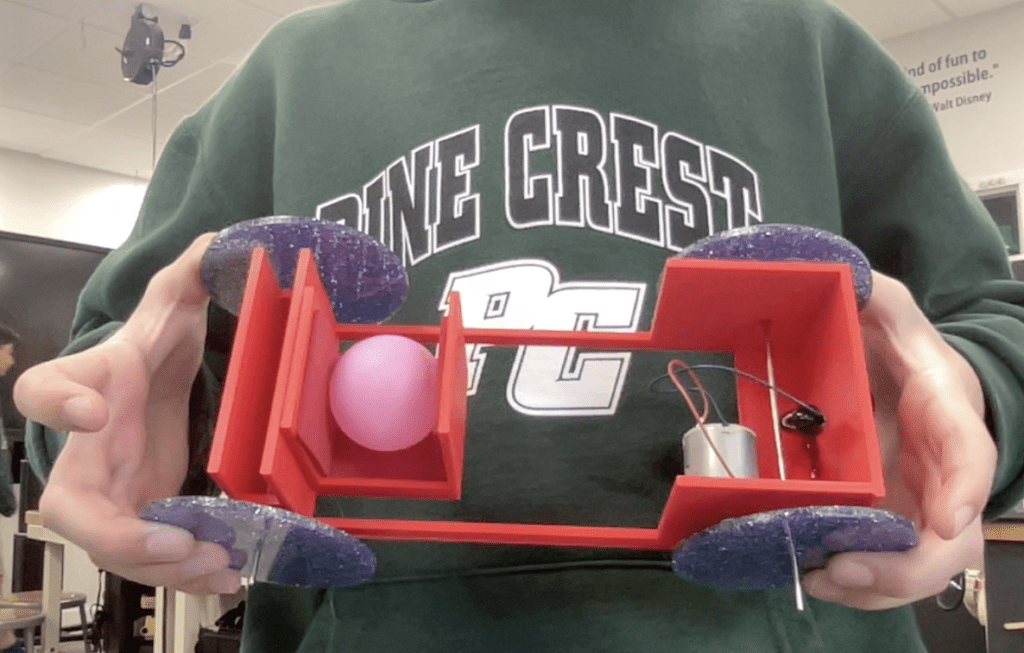

We have put in our motor, axles, washers, brass bushing and more, and we are ready to epoxy our wheels. We also added foam padding to keep the ball in place (Picture here was taken before foam padding was added. (Team Members Present: Adam and Jonah)

Entry 9: March 21 2022

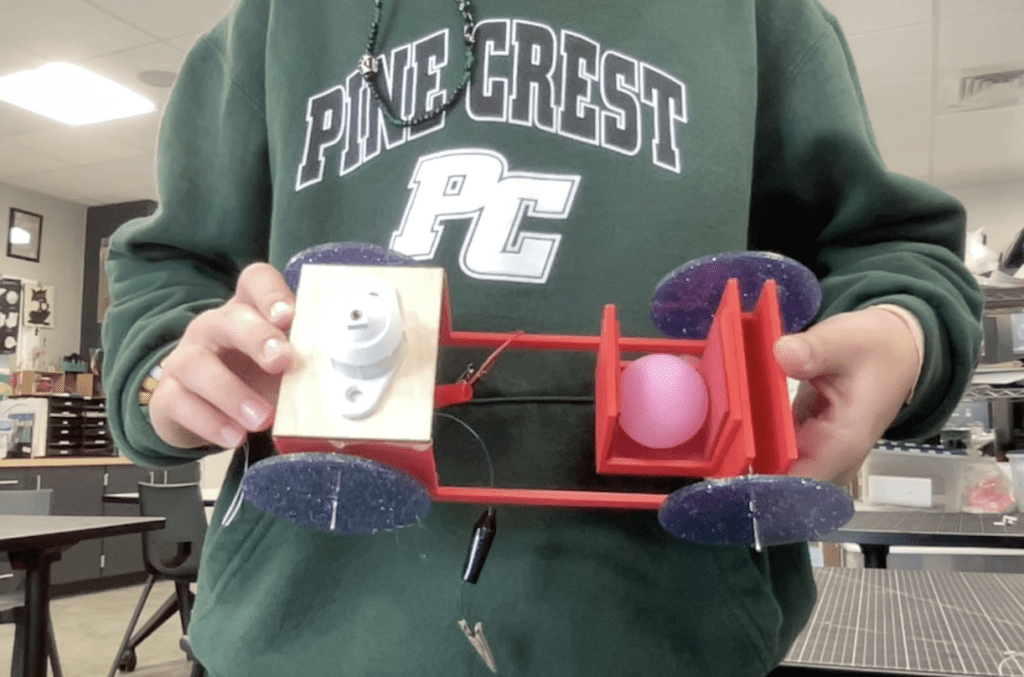

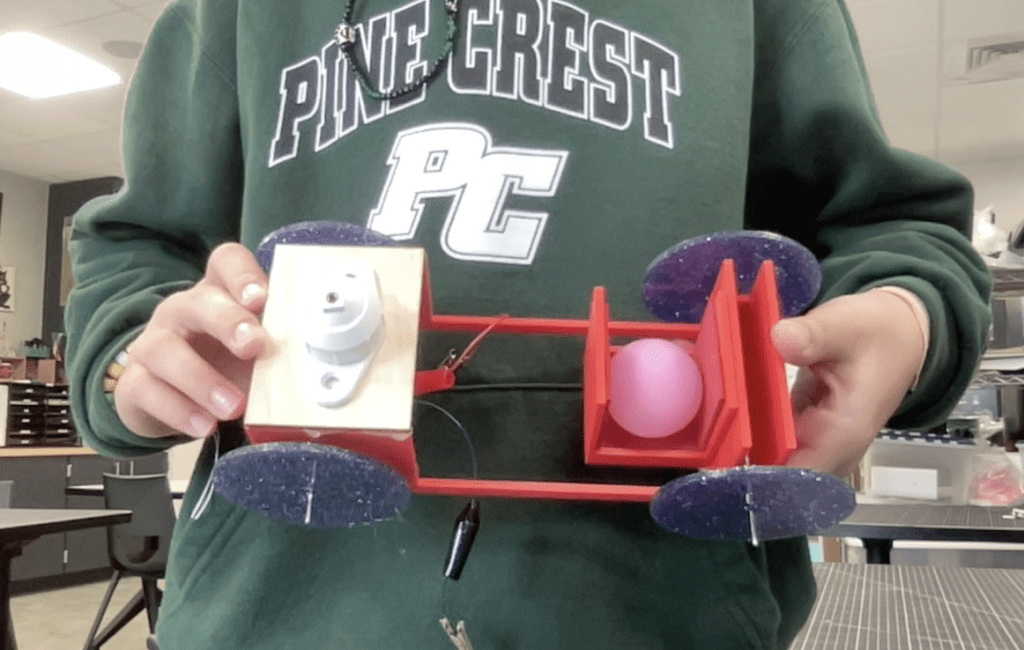

Turns out our wheels were too small, so we ended up epoxying wheels that are glittery but they are about 5 millimeters too large, so we are thinking about putting in a piece of wood and a ball-in-socket joint to attach the solar panel to. We can’t do that today because we are not allowed in the other room where we could do that. (Team Members Present: Adam and Jonah)

Entry 10: March 28 2022

When we added the joint, we thought it would be upside-down to how it is in the picture. Turns out this is how it works and we have a 7in. By 1in. Piece of wood that is being screwed into the ball-in-socket joint and is being attached to the solar panel. We tested out the car and it is very fast, but it turns. (Team Members Present: Adam and Jonah)

Entry 11: April 7 2022

We didn’t have engineering Monday due to a field trip so today we are finishing our car to participate in the schoolwide race to determine who will make it to Energywhiz. (Team Members Present: Adam)

Race Day (Bonus Entry): April 8 2022

Today we did a schoolwide race and raced our cars across a basketball court and we placed second with a time of ~9.58 seconds, nice! (Team Members Present: Adam and Jonah)

Entry 12: April 21 2022

Today we started working on our website and that’s really it for today. We didn’t make an entry last week or on Monday because of spring break. (Team Members Present: Adam and Jonah)

Entry 13: April 25 2022

Today we put our journal into the website, filmed our video, and started finishing up our website! We are also still adding the battery pack to the car. (Team Members Present: Adam and Jonah)

Team Video

*Note: Gear ratio is actually 56 to 10!

Pictures (Including Pictures in Journal)

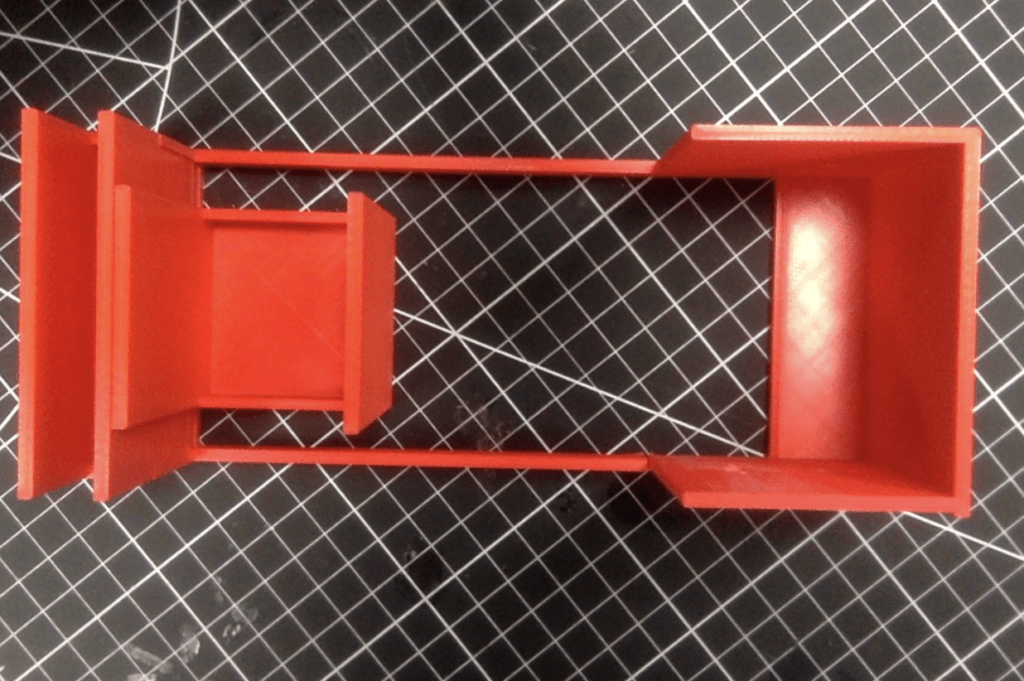

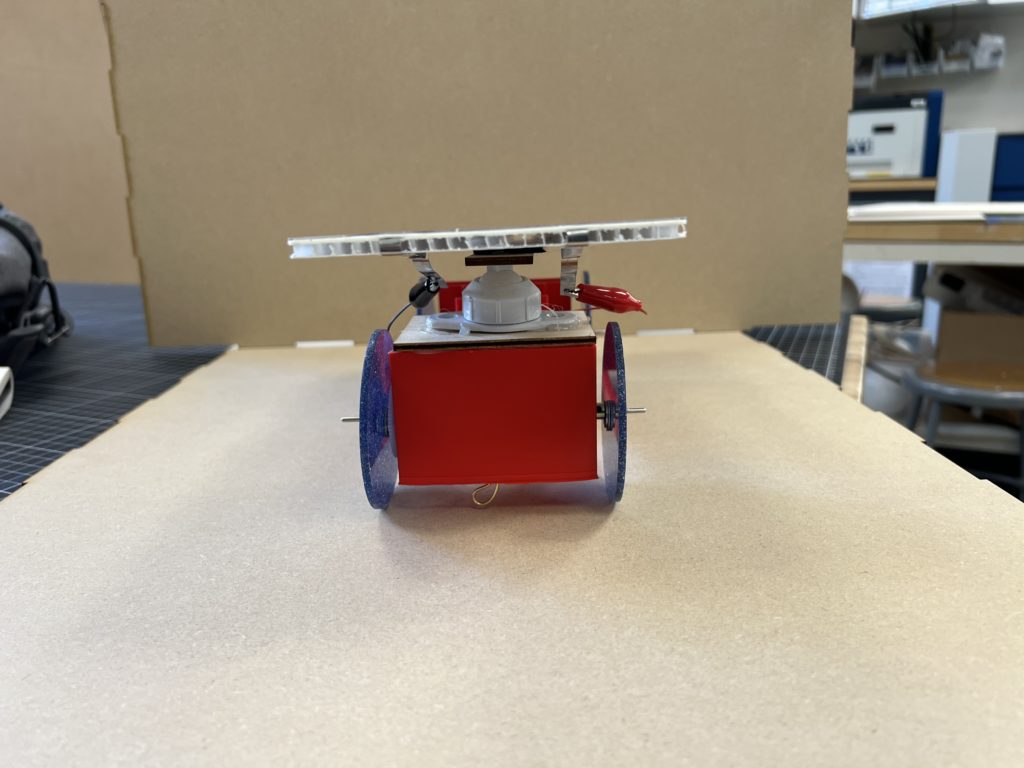

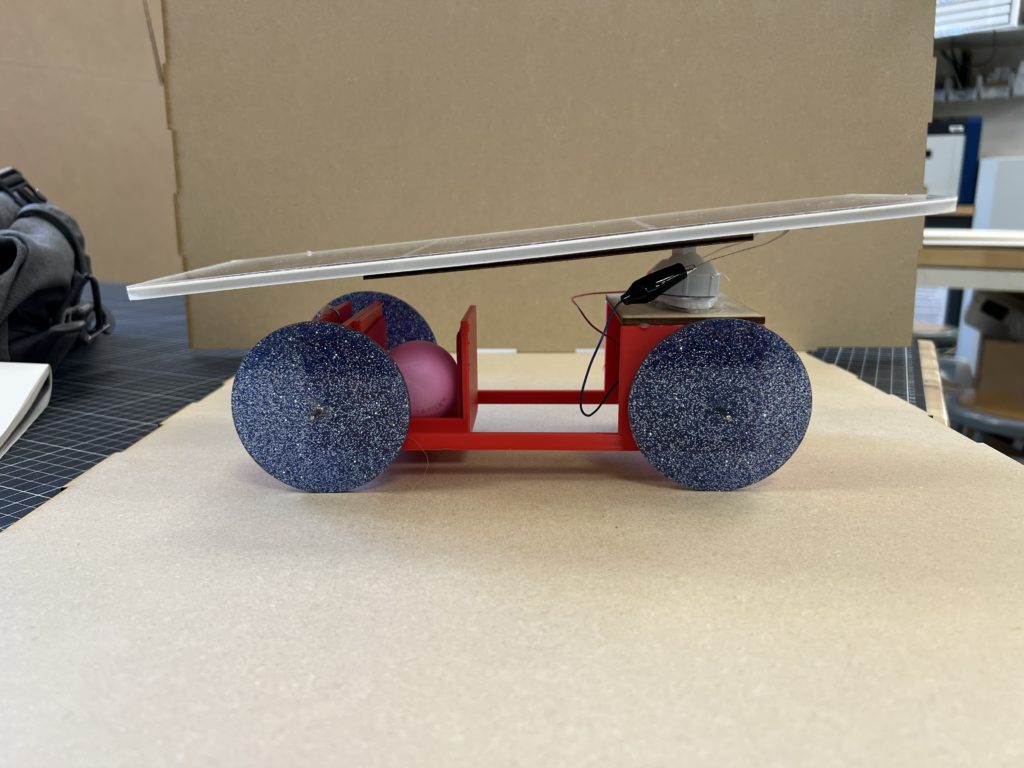

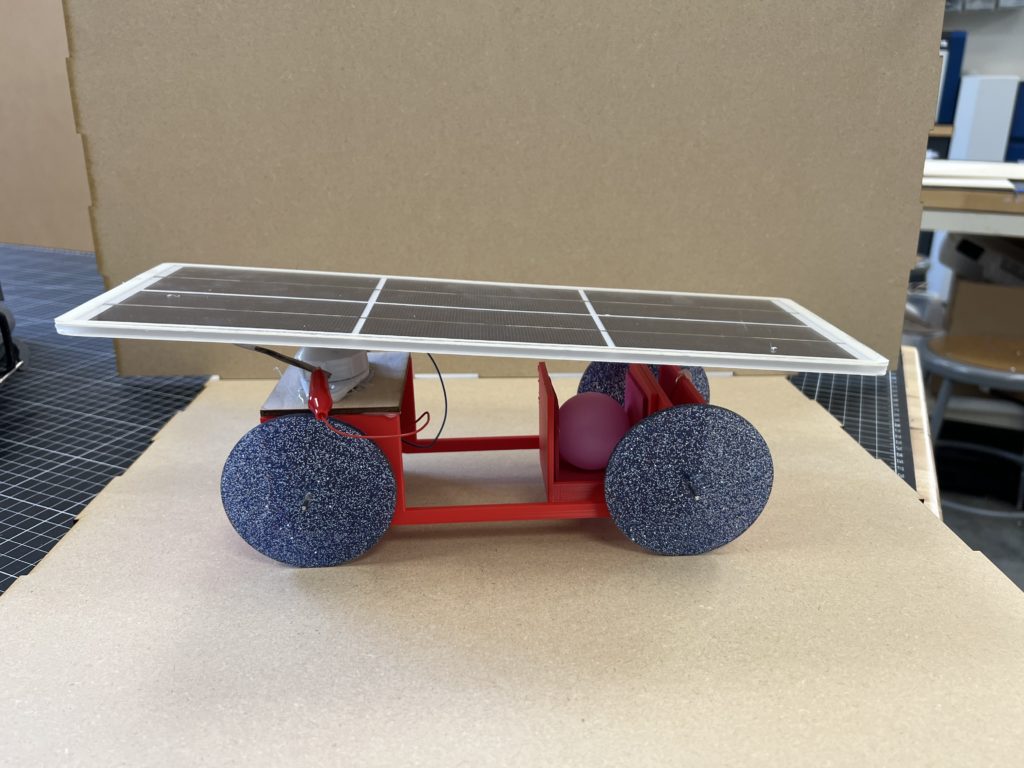

Above are the front side, the left side, the right side, the underside, the top, and the back side of the car.

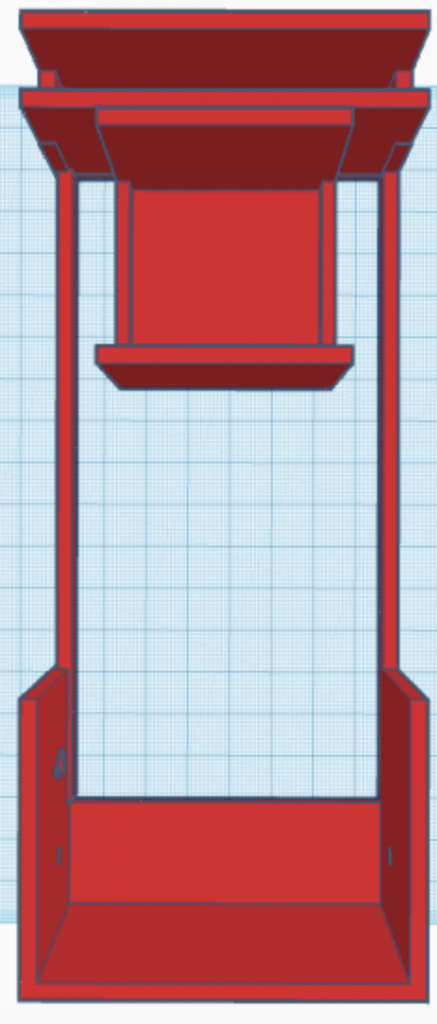

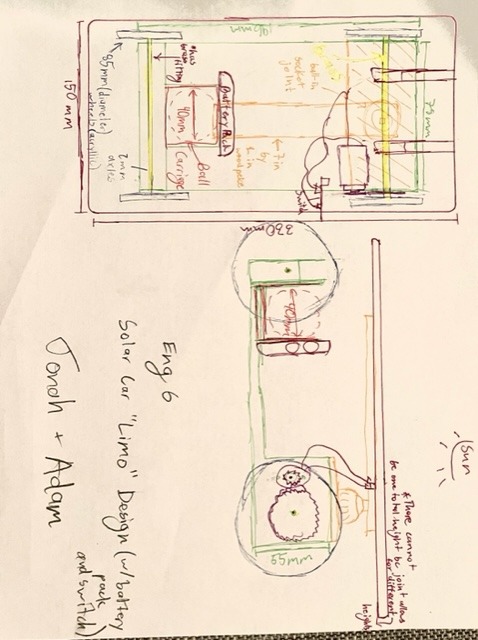

Here are the design drawings:

Q&A

Q: What’s the ball in socket joint for?

A: When we fitted our car with our new larger wheels, we found that we needed to elevate the solar panel so it wouldn’t rub into the wheels, so we used the joint to elevate the solar panel. Another reason we used the ball in socket joint as opposed to just a piece of wood is because the wheels were blocking the area where we would have taken the ping pong ball out of, so we had to use the ball-in-socket joint so we could change the angle of the solar panel to allow us to easily take out the ball and still put the solar panel in a position we would like during the race.

Q: Where’s the idea for foam padding from?

A: Originally we made a joke about our car being a luxurious limo and being “fitted with cushiony interior”. This gave us a great idea to add soft foam padding to the carriage for the ball because it actually helps keep the ball in place during the ride, and if you will, makes the ride, “more luxurious”.

Q: Why is your car so big/heavy?

A: Well, originally we didn’t fully think things through on our 3D model, but with the added size and weight comes a higher build quality and more solid car. We made sure to make everything secure and use materials that won’t break easily such as brass or epoxy. Those materials with the thick walls we made all add up to the weight, so we also made sure to have a solid, working gearbox that gives lots of torque to get the car up and running and fast as well, despite the large size and heavy weight.

Dimensions and Weight:

Base

The base of the car (red part) is 196 millimeters in length, 78 millimeters in width, and 55 millimeters tall.

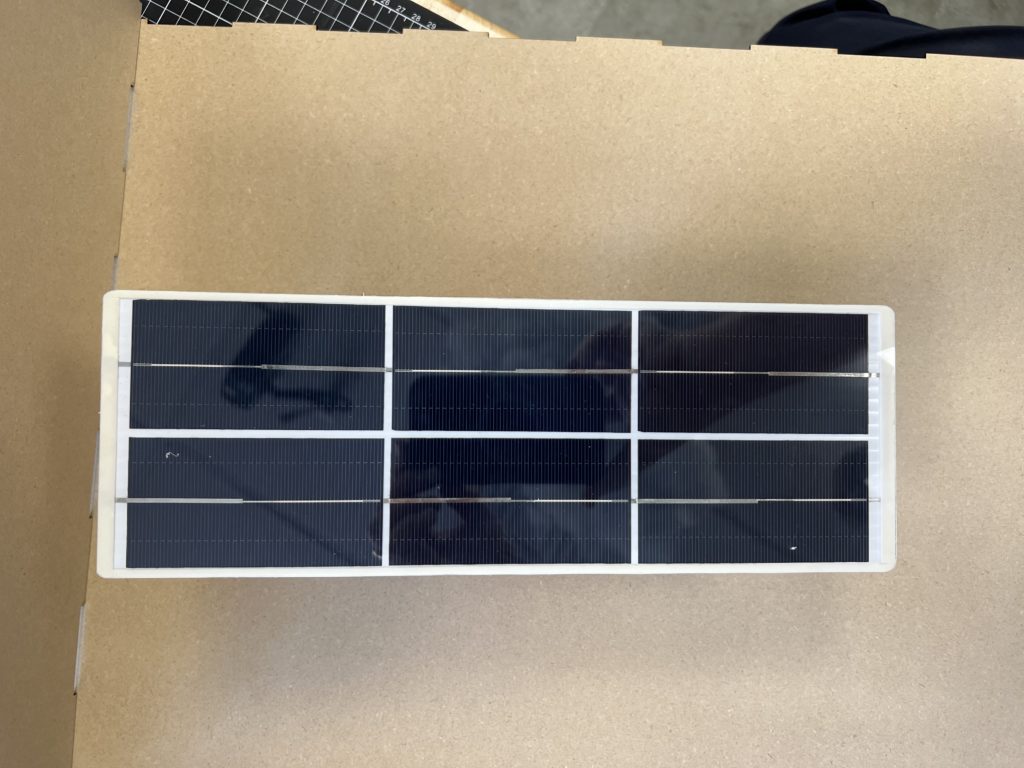

Solar Panel

The solar panel is 330 millimeters in length, 115 millimeters in width, and is 5 millimeters tall. The wood piece holding it up (that is attached to the ball in socket joint) is 177.8 millimeters in length (7 inches) 25.4 millimeters in width (1 inch) and 2-3 millimeters in height.

Weight

The current weight of the Limo is 353 grams (12.4517 ounces).

The way you arranged this page is very smart. Great job! This is incredibly in-depth.