Dave

Event Location: Cocoa-FL

Competition: Junior Solar Sprint

Division: 7-8 (JSS Blue)

School: CLC Hawks

Team Size: 2

Junior Solar Sprint Design Log

Car Name: Dave

| Team Member | Grade | Strengths |

| Logan B | 8 | Designing and measuring angles. |

| Jamie H | 8 | Building and being cool and has experience with competition. |

Time and Design Progress

| Date | Time Spent | Activities |

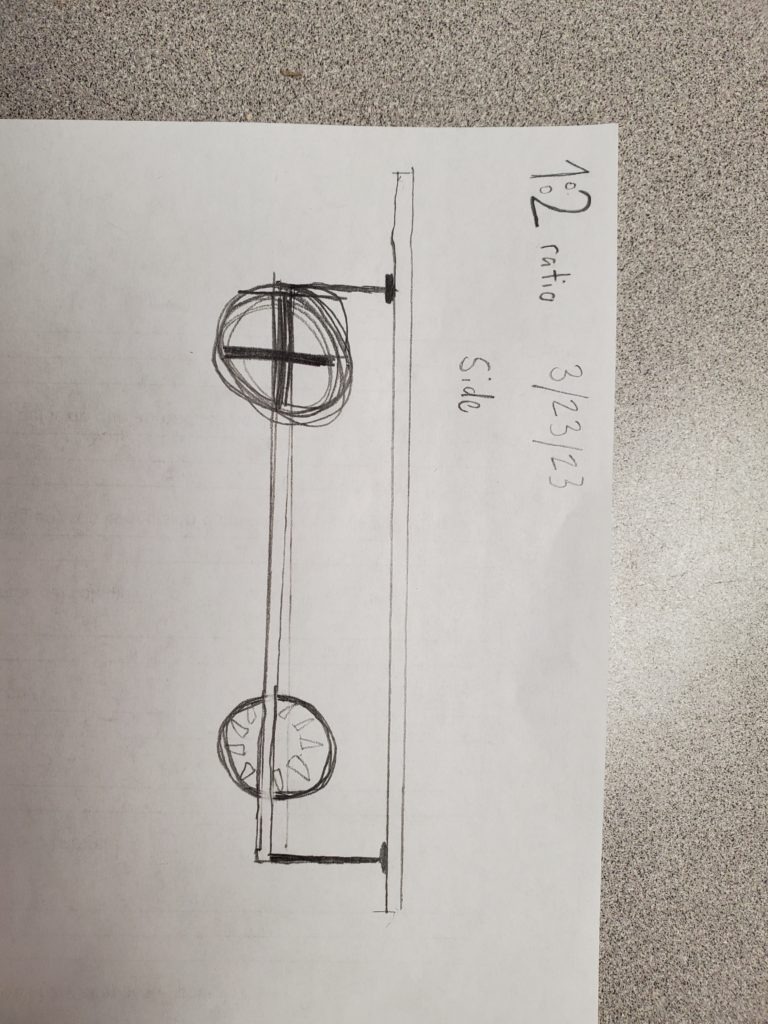

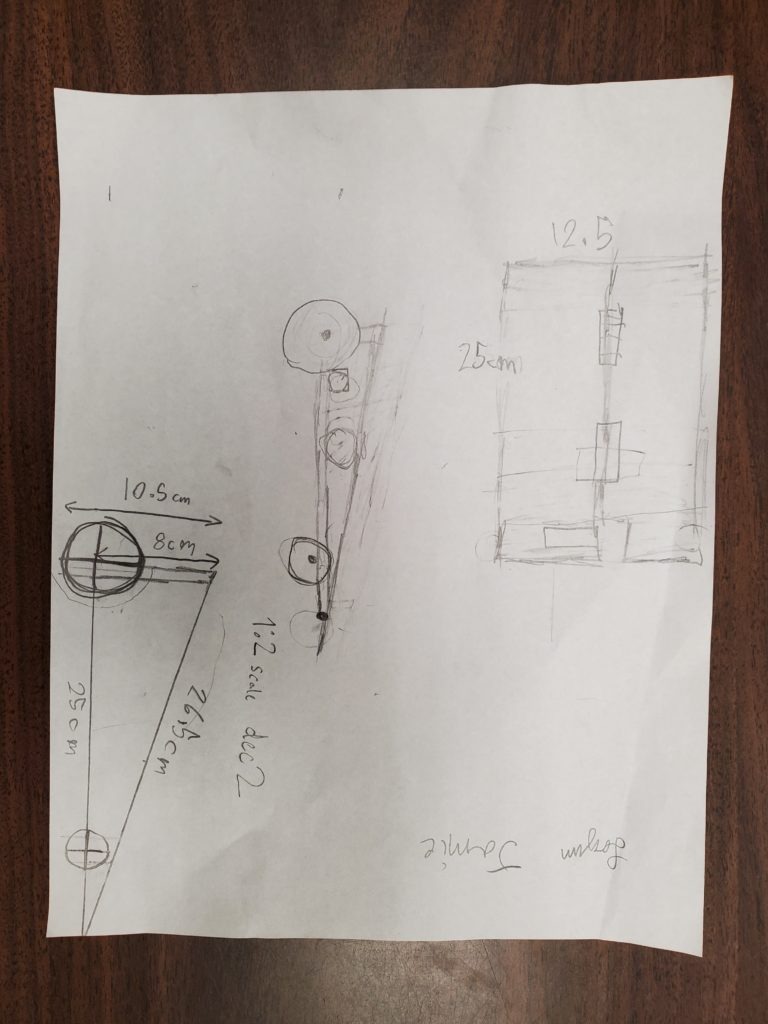

| December 2, 2022 | 1 hour | We made a rough sketch of our car and a more accurate sketch that had measurements of lengths and angles. It also had the correct proportions to our car at a 1:2 ratio. |

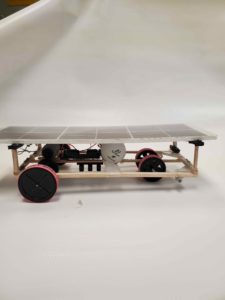

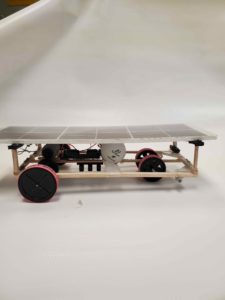

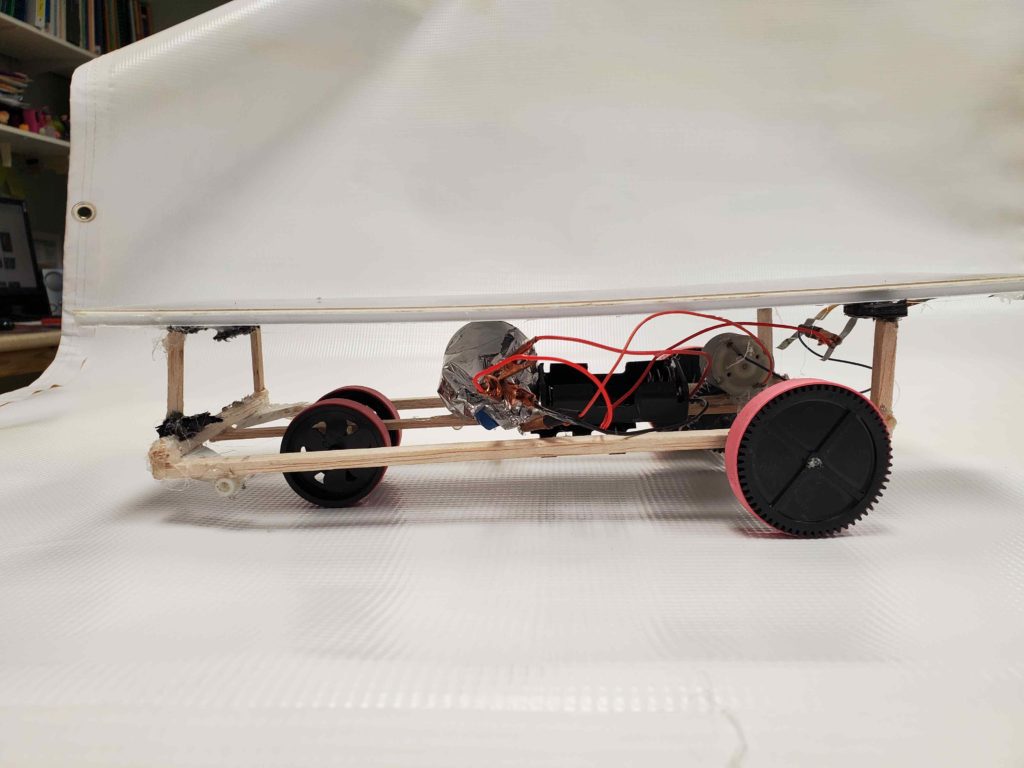

December 16, 2022 | 1 hour | We made the base for our car with balsa wood. and followed the plan we made last week. We had to measure out each piece to the marked measure on our design, we also had to make sure the base was symmetrical. |

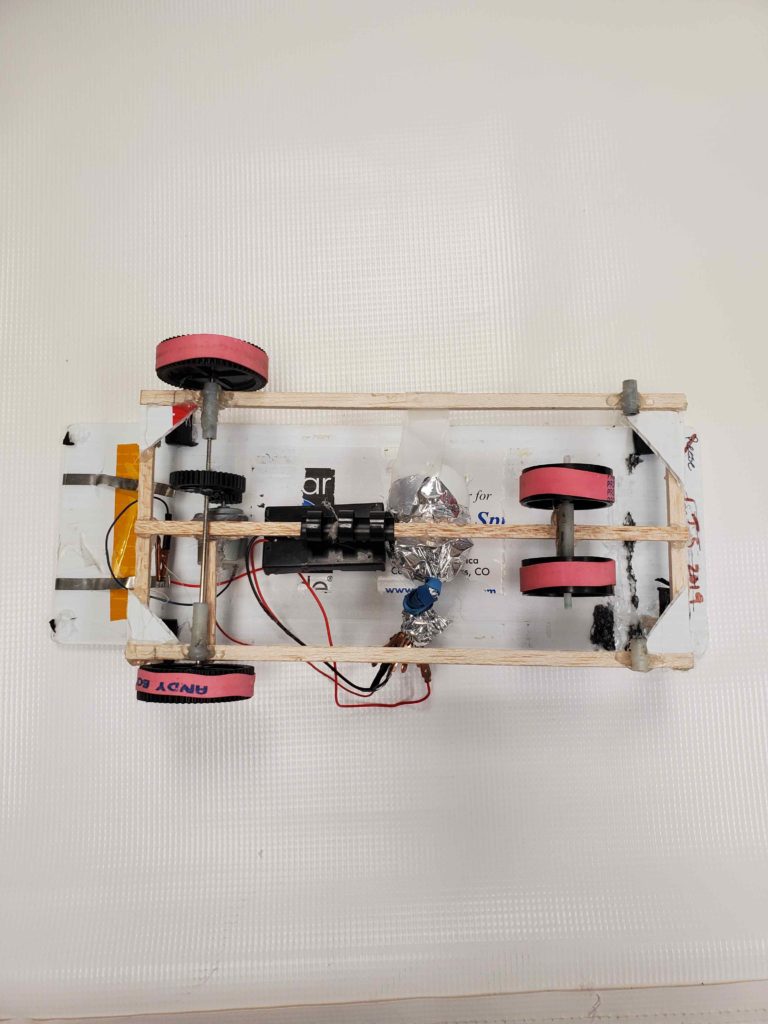

| January 6, 2023 | 1 hour | We worked on the wheels and axles on our car. It was hard to align them correctly so that the car would run straight. We also worked on fixing up our car if anything had not worked. |

| January 13, 2023 | 1 hour | We added the motor and battery pack and used a test run. It ran crooked so we had to do some axle adjusting. It did not run completely straight even then. |

| January 20, 2023 | 1 hour | We readjusted the gear on the motor in an attempt to make it more aligned. This is a problem but we just have to keep testing out different gear ratios to find the correct fit. |

| January 27, 2023 | 0 hours | Missed due to school trip. |

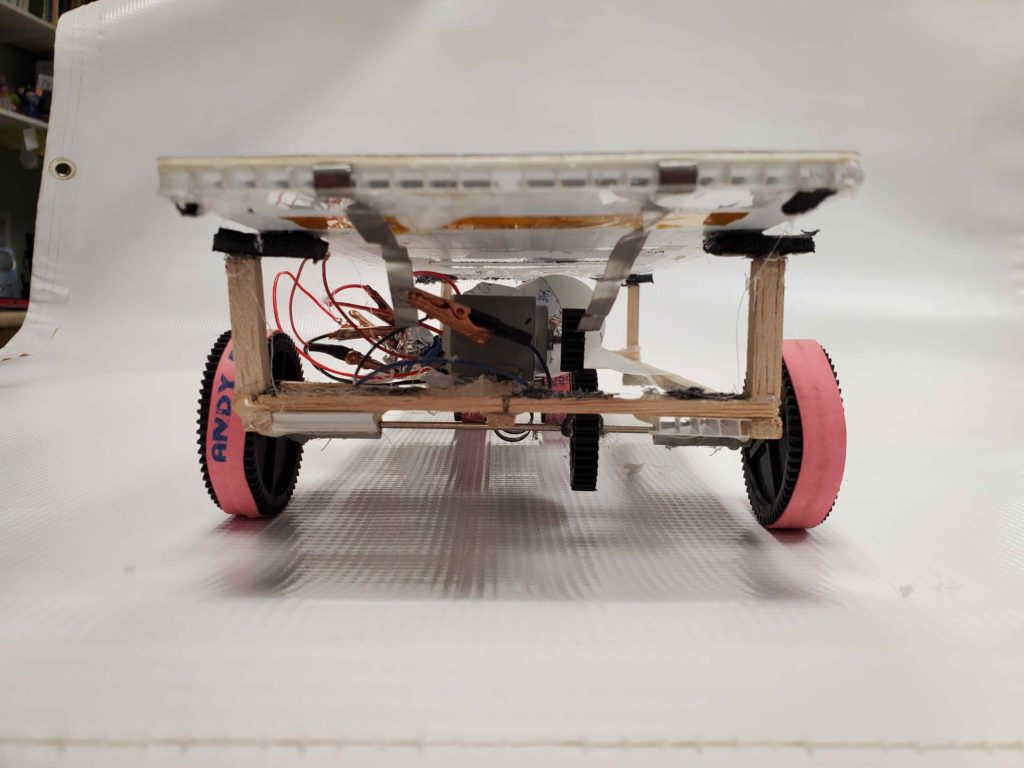

| February 3, 2023 | 1 hour | We aligned our gears more and added a support for our motor. We had to get the correct measurement so the support wouldn’t touch our wheels. We also tested new solar panel designs and worked on this log. |

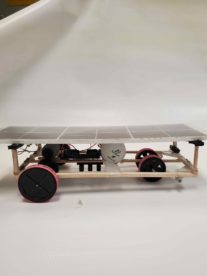

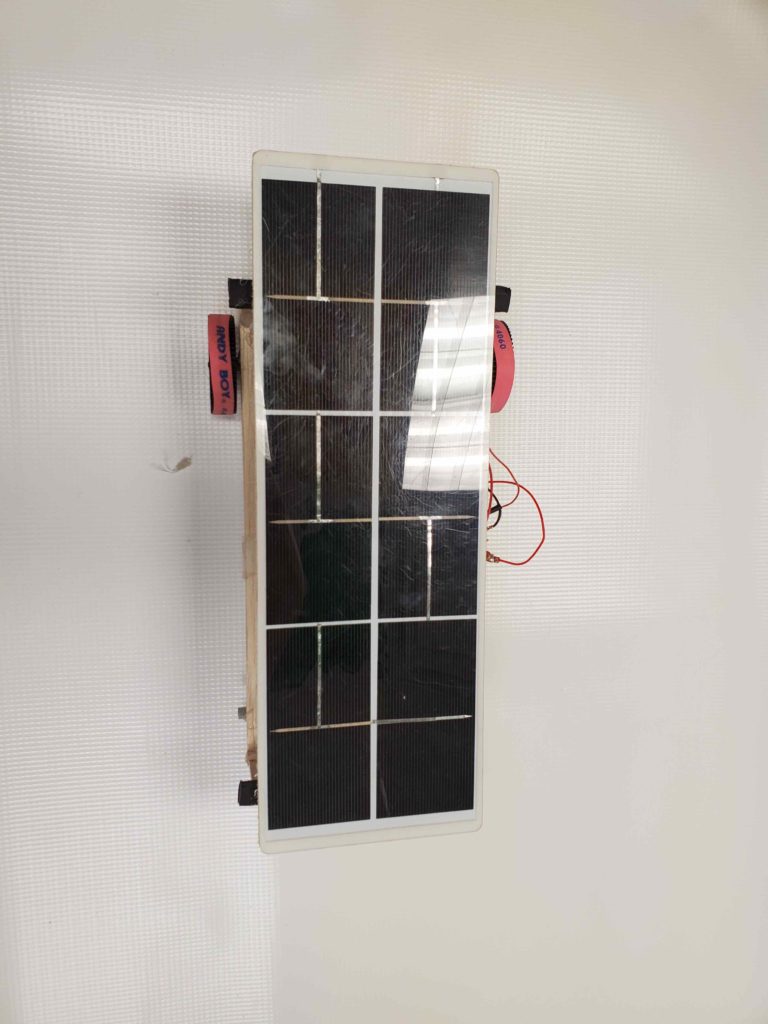

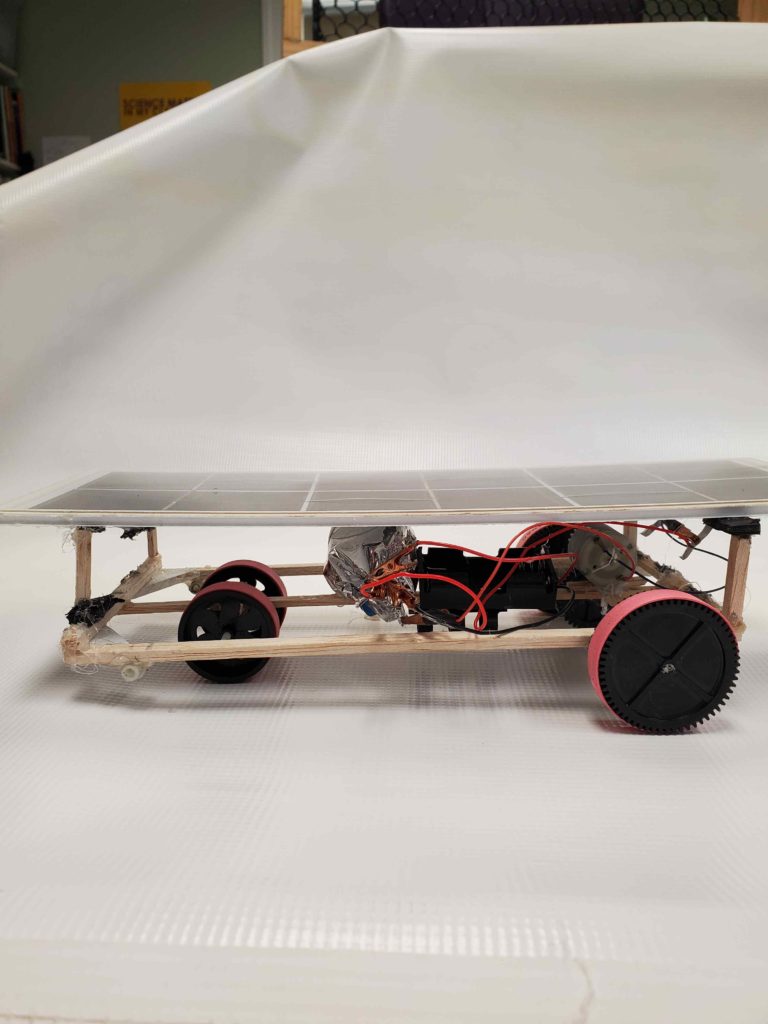

| February 10, 2023 | 1 hour | We tested out different ways of putting the solar panel on the car to have a balance of lightness, and aerodynamics. We initially planned to put our panel at a 10 degree slant for aerodynamics but after testing it, we realized that it made it way harder to catch direct sunlight. We decided that we wanted to have the panel lay flat on top of our car. |

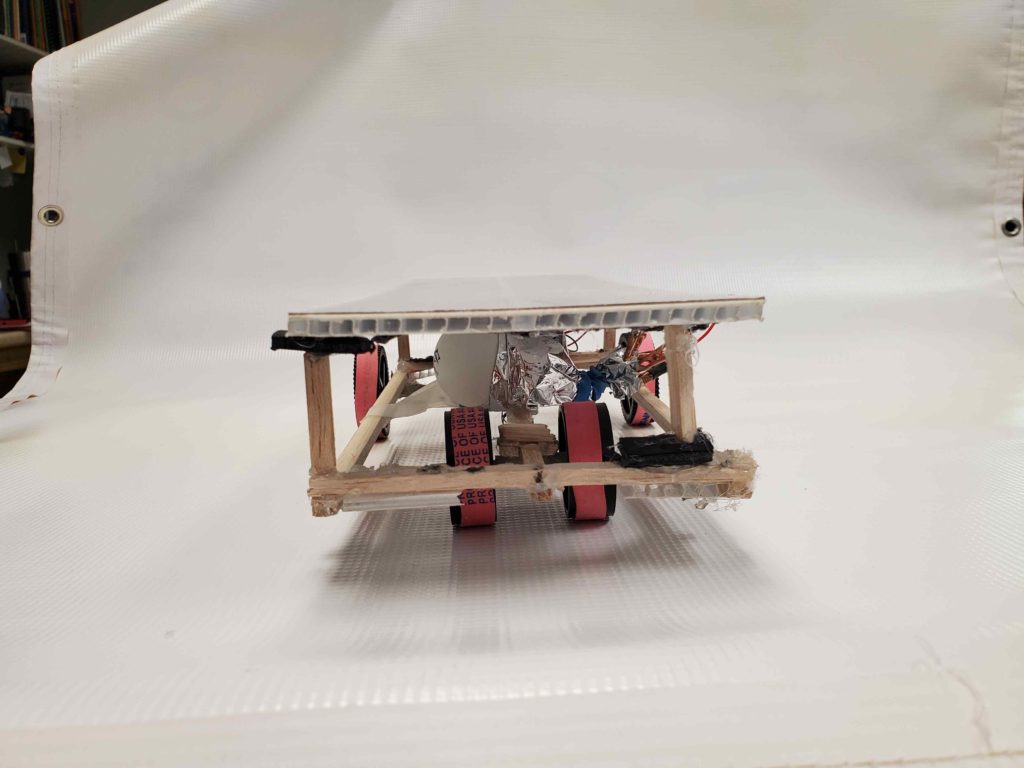

| February 17 2023 | 1 hour | Logan was absent so Jamie worked on another way to attach the solar panel but it ended up not working out so he had to scrap it. It had four slanted beams supporting the solar panel. It was too delicate so there was a risk of the car falling apart, and it was too heavy because it required extra supports that would not have been there if he didnt slant the beams. |

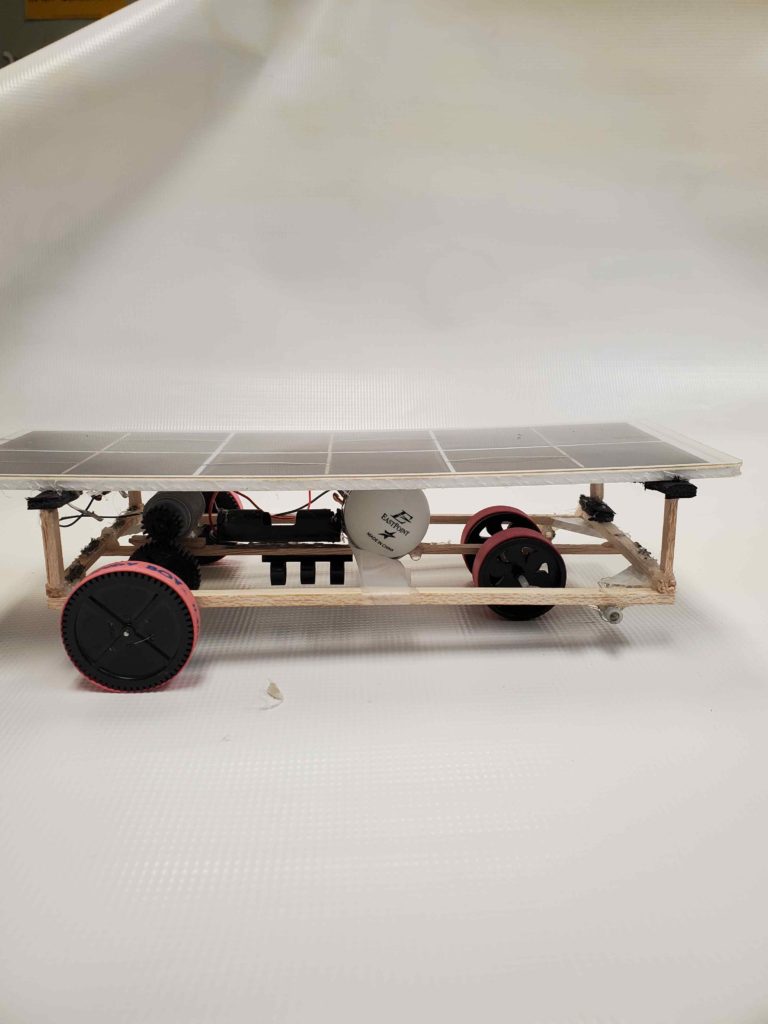

| March 8th | 30 minutes | We used a new front wheel design that was placed differently and used different wheels. This is because we felt that our current design rattled around too much and overall slowed down the car. The new design also significantly decreased the weight of our car. (it just made it look kinda weird) |

| March 21st. | 1 hour | We used a new way to set up the solar panel and attached the wheels in a way that it would go in a straight line and stay on sturdily. We also took photos and the video for our car. |

| March 23rd | 2 hours | We worked on the website and the log and shot the video where we talked about the car. |

| April 13th | 30 minutes | Logan worked on the website and finding a new way to hold the passenger as well as support some of the beams. Logan also tried out a new gear ratio. |

Design obstacles and changes made:

We had a large problem with how we set up the solar panel because initially it was slanted but the issue with that is that while it worked well it could only go when it was facing the sun which hindered its performance greatly this is where most of our issues were for the design.

Later during the regional race we had problems with the carrier for the passenger because the passenger would fall out but we fixed the issue by using construction paper so that the passenger could easily go in and out.

Dimensions of car: (height, width, length)

8.5cm 16cm 33cm

Weight:

206 grams

Wheel size(s):

≈14.13717cm circumference back wheels ≈12.56637cm circumference front wheel

Gear ratio (# of teeth on motor / # teeth on axle):

30/40

list of materials

All materials used are repurposed or recycled.

- coreplast

- 4 large gears: back wheels

- 2 thick wheels: front wheels

- four rubber bands for the wheels and one for the milar

- Balsa wood for the frame of the car and the 4 columns and supports

- 1 Battery pack

- 1 motor

- 1 really small gear for motor

- 1 small gear for axle

- 1 metal axle

- 1 plastic axle

- tape

- Foam

- 3 bushings

- Construction paper

- 1 piece of comb binding

Love the bases on these cars! Fixing the passenger issue with construction paper is a smart idea!